ICME Research Lab

Multiscale

Computational Mechanics for Linking Material Genome to Performance

|

This is research group of Prof. Alankar Alankar at Department

of Mechanical Engineering, IIT Bombay. Alankar graduated with a B.Tech (Metallurgical

Engineering) degree at IIT Roorkee, India, MASc (Materials Engineering)

degree at The University of British Columbia, Canada and PhD (Mechanical

Engineering) at Washington State University, USA under the supervision of

Prof. David Field. After doctoral degree, he did postdoctoral research at

Max-Planck Institut fur Eisenforshung, Germany under mentorship of Prof.

Dierk Raabe and Prof. Philip Eisenlohr. His second post-doc stint was at Los

Alamos National Laboratory, USA under the mentorship of Dr. Ricardo

Lebensohn, Dr. Carlos Tome and Dr. Alfredo Caro. Subsequently he joined

Modumetal, Inc. in Seattle, USA where he was responsible for design and

architecture of metal nanolayered coatings. His area of research consists of

dislocation theory, crystal plasticity modeling, multiscale modeling of

microstructure evolution, nanolayered materials, creep, irradiation damage,

wear and degradation of materials and other regime of structure-property

relationship. |

|||||||||

|

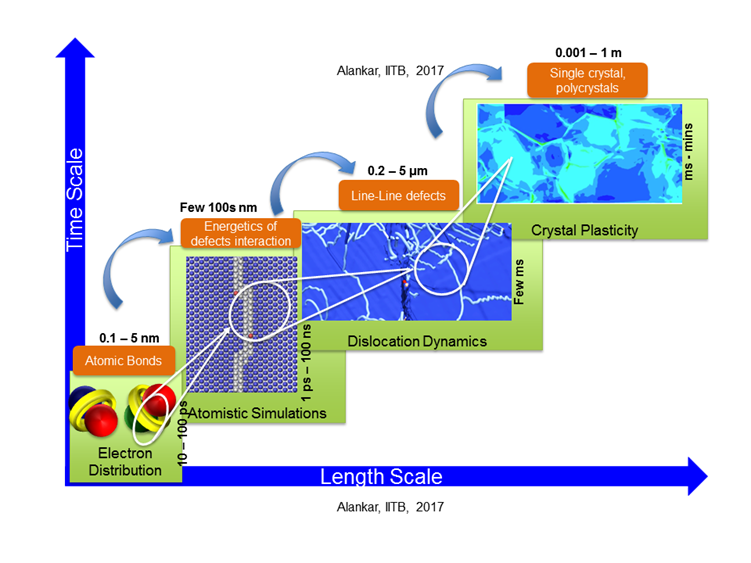

We work

in the area of development of improved methods of multiscale modeling of

deformation and length scale bridging. The key areas of interests are Crystal

Plasticity, Multiscale and Multi-physics problems, Dislocation Dynamics,

Atomistic Simulations relevant to plasticity and deformation. Our major

effort is in open-source code development or development of new modules for

existing codes.

|

|||||||||

|

Crystal Plasticity |

|||||||||

|

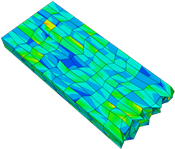

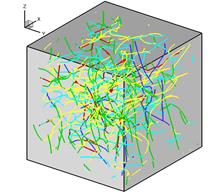

Deformation Microstructure Plastic deformation in metals is caused by movement of dislocations

the line defects present in metals. Crystal lattice remains invariant after

the crystallographic slip, as compared to the elastic distortion which changes

both, the crystallographic orientation and the spacing of a crystal lattice.

Apart from accounting for the plastic deformation in crystalline materials,

dislocations are associated with work hardening behavior by means of their

multiplication activity due to mutual interactions that hinders the motion of

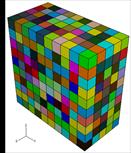

gliding dislocations. To model the plastic deformation, crystal plasticity

(CP) is used. The crystal plasticity formulations have successfully addressed

the problems like rotations of individual grains in a polycrystal, evolution

of crystallographic texture using classical hardening models e.g. power laws

defining crystallographic slip. A CP model assumes material as continuum body

and maps the elastic and plastic deformation using crystal kinematics. To get

the stress-strain response of polycrystals, mean-field and full field

approach can be used which may need Finite Element or Fourier Transform based

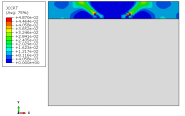

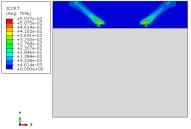

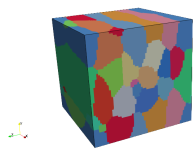

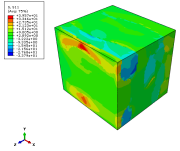

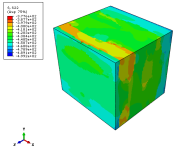

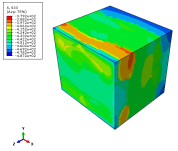

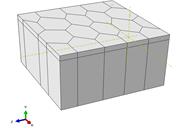

numerical methods. In the example, the CP model is run for polycrystal of

ferritic-austenitic and ferritic-martensitic dual-phase (DP) steel with

microstructure having 50 grains. The grain reorientation during deformation

is also shown for the above two cases. |

Microstructure

of 50 grains polycrystals

Stress

distribution for ferritic-austenitic DP steel

Stress

distribution for ferritic-martensitic DP steel |

Grain re-orientation and fragmentation in

ferritic-austenitic DP steel

Grain re-orientation and fragmentation in

ferritic-martensitic DP steel |

|||||||

|

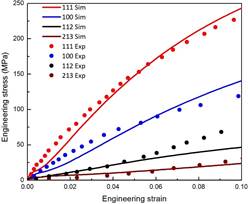

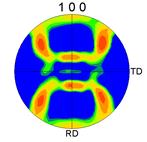

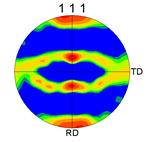

Understanding Bulk Metal Deformation Most of the materials are polycrystalline in nature. The difference

between a single crystal and a polycrystal material are the grain boundaries.

Grain boundaries play a major role in strengthening the material. To

understand the behavior of a polycrystalline material completely we need to

track the orientations of grains during deformation. Crystallographic texture displays the anisotropic nature of the

material and is used as a nob for designing mechanical properties. |

Understanding Single Crystals

Understanding Single Crystal Behavior |

Crystallographic Texture Evolution |

|||||||

|

|

|

||||||||

|

Understanding Dislocations at Small

Scales |

|||||||||

|

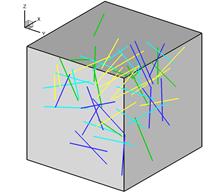

Dislocation Dynamics The mechanical response of materials alters drastically as the size

of specimen becomes less than a few microns. As such small structures are

getting attention in modern technologies, there is rising need to model and

understand elastic, plastic and fracture behavior. Plastic deformation in

crystalline materials occurs due to glide of dislocations. Work-hardening in

metals occur due to dislocation multiplication and interaction between them.

In order to model the dislocation activity and interaction between them,

dislocation dynamics (DD) is often used. In DD, the dislocation sources are

represented by discrete line segments gliding due to numerous driving forces

such as externally applied forces, dislocation line tension and interacting

forces between dislocations. DD simulates behavior of dislocations

individually and interaction between them and supplies mechanical response

and detailed analysis of evolution of microstructure. |

Undeformed

Configuration

Deformed

Configuration |

||||||||

|

Advanced Computational Methods |

|||||||||

|

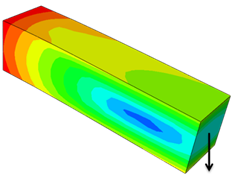

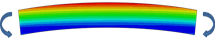

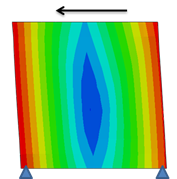

Bridging Length Scales Dislocations in a

crystal influence heavily as the size of the specimen decreases to micron

level. There is an absolute indication of size effect through indentation

experiments, micron beam bending tests and torsion tests. New dislocations

arise due to inhomogeneous deformation which is purely geometrical in nature.

These geometrically necessary dislocations add to the already existing

dislocations creating size effect i.e., smaller is stronger. GNDs contribute

to strengthening of composites as well. |

Cantilever

Beam

Pure

Bending |

Simple

Shear |

|||||||

|

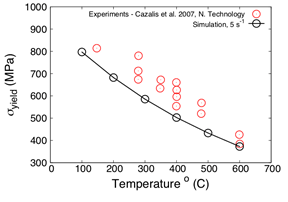

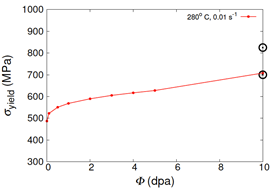

Irradiation Effects: Hardening,

Creep and Growth Reactivity

initiated accident (RIA) or loss of coolant accident (LOCA) in a nuclear

reactor may lead to sudden temperature rise. Accidents caused by LOCA

condition or RIA condition may lead to a dynamic expansion of fuel pallets.

This results into a multiaxial state of deformation caused by high thermal

loading (1000 s-1) in presence of extreme conditions of

irradiation. |

Effect of

Temperature and Irradiation Dose on Yield Stress

Yield

stress as a function of dose |

Residual

Stress in a Zr polycrystal due to Growth |

|||||||

|

Mechanical Performance Analysis |

|||||||||

|

Thermal Barrier Coating This study aims at to improve thermal efficiency of IC

engines by reducing heat loss

from the gases inside the combustion chamber to coolant. One promising

technology to reduce heat transfer to coolant is application of thermal

insulation, often referred as thermal barrier coatings (TBC), on the inner

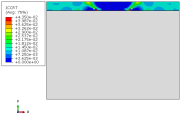

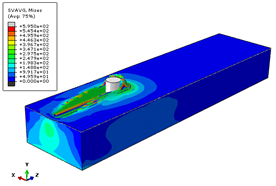

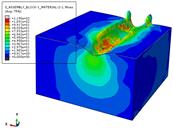

walls of the combustion chamber and on the top surface of the piston. Damage modeling in TBC The modelling of damage in TBC is carried out by using

commercial finite element analysis software ABAQUSTM. A

thermomechanical model is developed with material properties as a function of

temperature. A

more realistic microscopic model is created with preferred orientations of

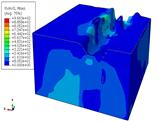

crystallites. Dynamic Deformation Wear is defined as unwanted removal of material on application

of mechanical load. In the present work we study the micro-plowing mechanism

of wear in which material is not removed but displaced to the sides. Finite Element Model for Wear Analysis The large deformation problem is often difficult to solve by

classical Lagrangian finite element approach. The test block is taken to be a

rectangular block of size 20 mm X 10 mm X 80 mm. The model is composed of two

parts: indenter and the workpiece. The indenter is assumed to be cylindrical

with a hemispherical tip in shape. The indenter is discretized under a

Lagrangian frame while workpiece as an Eulerian frame. The Eulerian region

was divided into two sections, filled elements, and the other was set with

void elements to visualize the material flow. In second case the material

work-piece is modeled with simple rectangular block (20 mm X 20 mm X 10 mm)

and block with 20 grains of which material properties varies from factor 0.1

to 2 of the base aluminum material. |

Damage induced

in TBC for a) 0.1 mm and b) 0.3 mm and c) 0.5 mm TBC thickness

Stress

Distribution in polycrystalline model

Development of Coupled Model

Microwear of a Polycrystal |

||||||||

|

Computational The

group is supported by the following computational facility: 1. Small

HPC Linux cluster with 8 nodes with 170 cores total 2. 32

Core Windows Workstation with GPU 3. 20

Core Unix Workstation with GPU 4. 24 TB

Data Cloud 5. Small

Workstations for Students PS:

Please feel free to contact for usage of resources. Experimental 1.

Calowear Test for Microwear and Coating Thickness up to 200 nm 2. Taber

wear test for Abrasion Test 3.

Pin-on-disk test |

Taber Wear Test

Calowear

Test |

||||||||

|

|

|||||||||

|

Current

BTech students / interns who are good at Applied Mathematics, Numerical Integration,

C++, C, MATLAB scripting, FORTRAN, Python / python based tools or are willing

to learn the above on Unix based environment, are welcome to contact. 1

Position for MTech student is available. The project is in collaboration with

DMRL, Hyderabad. 1 BTech

/ MTech project available. The project is in collaboration with BARC. 1

position for a PhD student is available. |

|||||||||

|

Contact |

|||||||||

|

Please feel free to contact us at the following for collaborative

research work, projects or consultancy for multiscale modeling. Alankar Alankar, Ph.D. Assistant Professor,

|

|||||||||