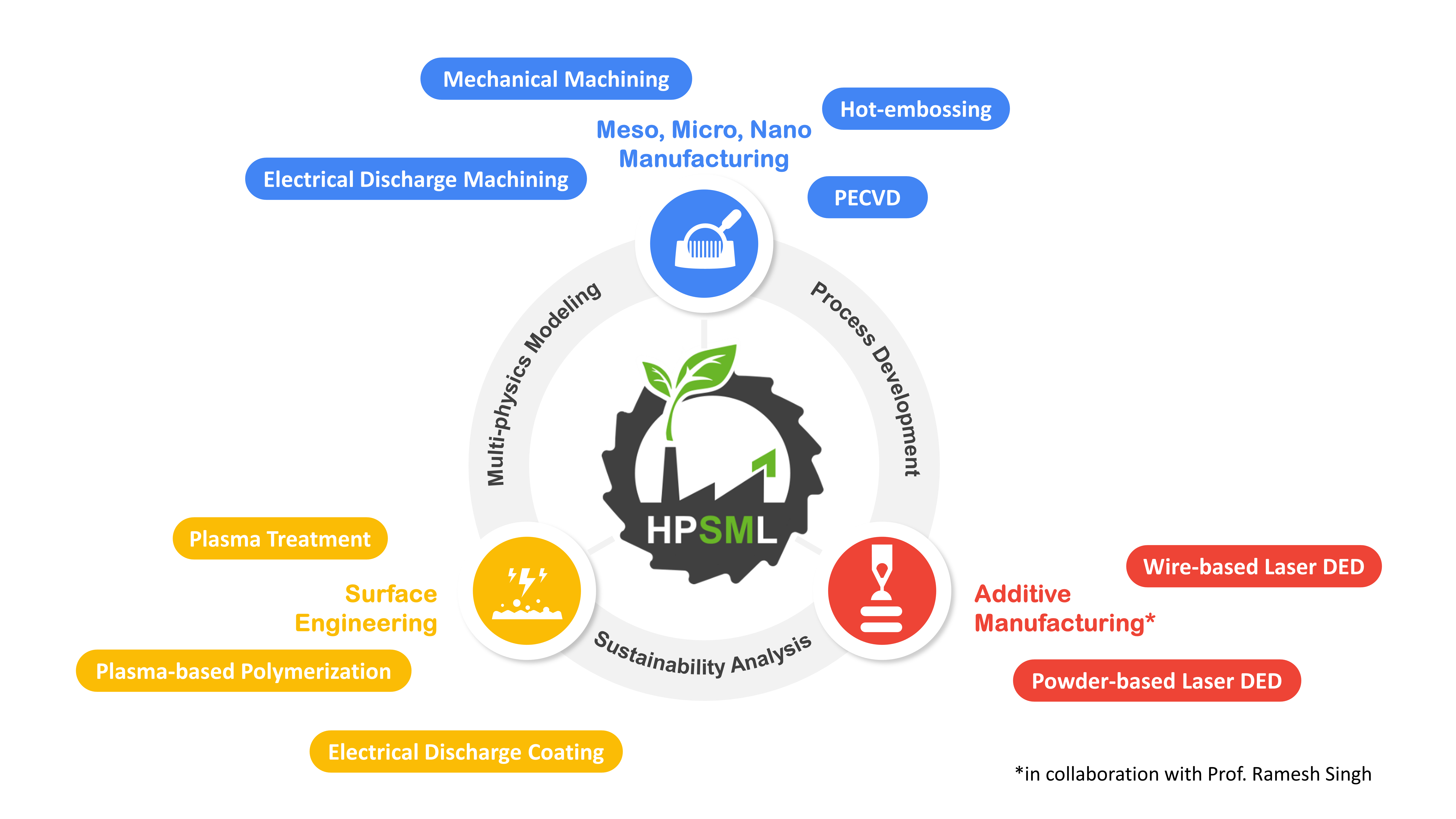

Our research approach consists of:

Multi-Physics Modeling: We utilize advanced modeling techniques to analyze existing manufacturing processes. This approach helps us gain deeper insights into the underlying mechanisms, enabling us to identify pathways for productivity improvements and enhanced process control.Process Design and Development: We focus on designing and implementing novel micro- and mesoscale technologies to enable more effective manufacturing practices. This includes the exploration of new materials, methods, and tools that can meet current and future industrial demands.Sustainable Analysis: We assess the environmental impact and resource use of advanced manufacturing processes, with a focus on improving energy efficiency. Our goal is to support cleaner production and promote long-term sustainable practices in engineering.

Research Areas

Below are some selected

Sponsors

Sponsored Projects

| Duration | Description | Funding (106 INR) | Sponsors |

|---|---|---|---|

| 2023-2026 | Improved Adhesion and Corrosion Resistance for Marine Applications via |

5.3 | Mazagon Dock Shipbuilders Ltd. |

| 2023-2026 | Development of Atomized Dielectric-based |

7.3 | Water Technologies Cell |

| 2023-2026 | High-performance |

6.3 | Core Research Grant |

| 2023-2026 | Multifunctional |

15.7 | IMPRINT-IIC.2 |

| 2019-2024 | Development of Micro/nanobubble-mixed |

8.8 | IRCC |

| 2019-2022 | |

3.1 | Start-up Research Grant |